- Problem Definition

As new Oil and Gas Operator, currently we are in the preparation of FEED phase in developing their new offshore facility. A well-structured WBS is need to be prepared before it deliver to the FEED Contractor as a basis of their deliverables. The objective is to select optimum WBS that could facilitate the future Offshore Gas Development Project.

- Identify the Feasible Alternative

There are 4 WBS that being considered to facilitate above objectiveCurrent WBS

A. Current WBS

Built on non-standard WBS that potentially will have a problem during the execution since it will required number of mapping process in its implementation.

B. OmniClass

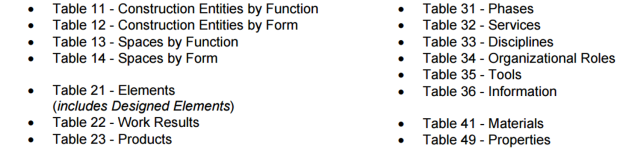

OmniClass is use faceted classification, where several tables that describe objects in the Built Environment from various points of view. Each table can be used separately to compose a particular subject or combined with other tables to construct a more complex subject. [1].

Fig.1: OmniClass tables

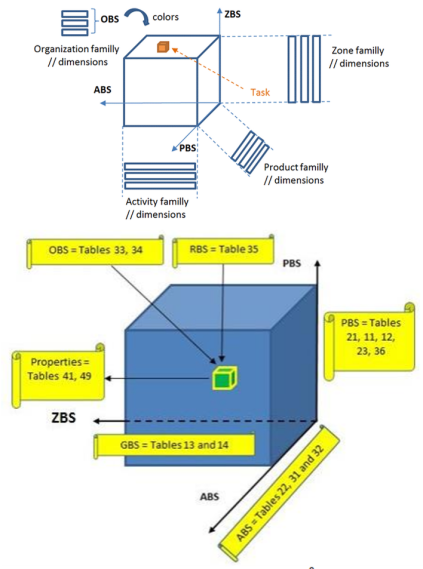

These 15 tables however can be simplified since it belong to the same family, mean either Zone, Product, Activity or Organization dimensions. Hence, we can have parallel dimensions to the 4 main dimensions (ZBS, PBS, ABS and OBS) [2]

Fig.2: OmniClass tables – Grouping within family

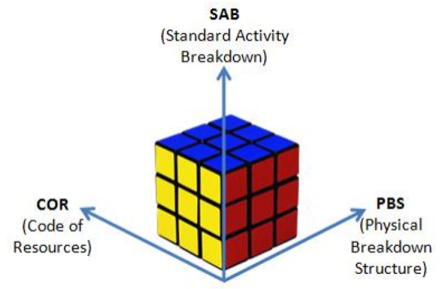

C. Norsok Z-014

NORSOK standards are developed by the Norwegian petroleum industry intended to replace oil company specifications and serve as references in the authorities’ regulations. [3]

The system comprises 3 sets of complementary sub-coding systems named:

- PBS (physical breakdown structure)

Hierarchical structure which defines the physical/functional components of oil and gas facilities/projects during any development.

- SAB (standard activity breakdown)

Defines all resources necessary for the planning and execution of an oil and gas project/facility.

- COR (code of resources)

Identifies the individual records/items/lines/components/elements of estimates which when summarized comprise physical functional areas (PBS) and which occur during the different development phases (SAB).

Fig 3: Illustration of NORSOK Standard Z-014[4]

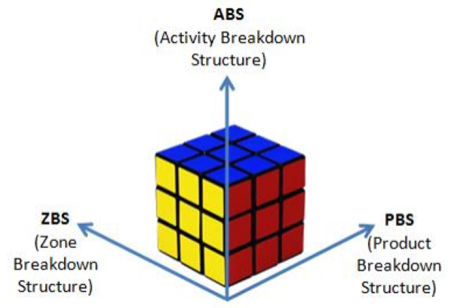

D. 3D WBS

In 2012, Jean-Yves Moine has developed a concept of 3D Work Breakdown Structure (3D WBS) with 3 tree structures that compose the WBS [5]:

- ZBS (Zone Breakdown Structure).

Physic-functional areas, functional zones or topographical locations. In EPC (Engineering, Procurement, and Construction) project, ZBS is group of functional system for the design and the commissioning phases. For construction phase, ZBS is geographical area.

- PBS (Product Breakdown Structure).

Generally PBS is equipment, material, deliverables, civil works components; and functional systems at the higher levels of the tree.

- ABS (Activity Breakdown Structure)

An activity is an action, in process point of view. Activities are deployed on products. It is the processes that build products. For example: studies, design, purchase, construction and installation.

Figure 4: Illustration of 3D WBS[4]

- Development of the outcome for Alternatives

There are three (3) criteria that have been selected as parameters to analyze and compare the above alternatives:

- Level of details of Offshore facilities, this will explain how detail each alternative in facilitating Offshore facilities requirement

- Complexity, how complex the structures will be

- Work flow of activities, is how the activities work together from the project scope development to the final design.

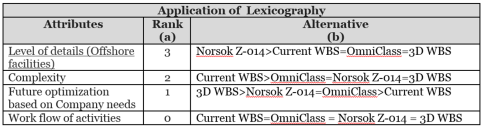

Lexicography, one of non-compensatory models for multi attributes decision making technique, has been chosen to compare and analyze the alternatives.

- Selection of Criteria

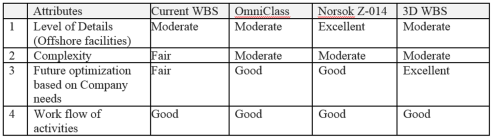

Each WBS comparison of the attributes is expressed below:

Table 1 – Summary Information of Engineering Design Stage WBS

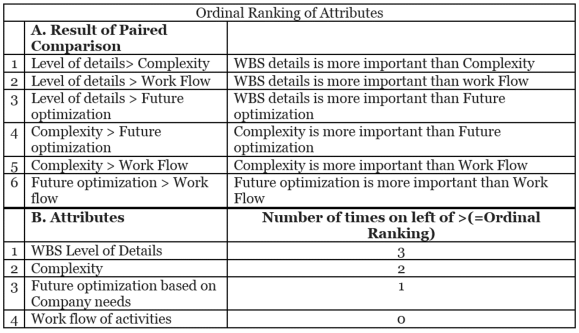

All attributes in table 1, be ranked in order of importance by doing paired comparison between each possible attribute combination. Result as shown on below table :

Table 2 – Ordinal Ranking of Attributes

- Analysis and Comparison of the Alternatives

Based on table 2, the ranking is found to be:

WBS Level of details > Complexity > Future optimization > Work flow of activities

Table 3 – Ordinal Ranking of Attributes

Note:

(a) Rank of 3 = Most Important, Rank of 0 = Least Important

(b) Selection is based on the highest ranked attribute

- Selection of the Preferred Alternative

Considering the above ranking, the Norsok-Z014 is typically the solution for the Offshore project, current WBS need to be adjusted to accommodate the standard. However when further goal is gain the standardization and optimization, then by refer to the second highest rank combination between 3D WBS and Norsok-Z014 will give a greater advantage for the Offshore Project.

- Performance Monitoring and the Post Evaluation of Result

Periodically, consistency of utilizing designed WBS need to be review. Also further development is required to accommodate future needs and future information related to the new technology.

References :

- (2013). OmniClass™: a critique – Practice management article from NBS. Retrieved from http://www.thenbs.com/topics/practicemanagement/articles/OmniClasscritique.asp

- CUBIX PROJECT MANAGEMENT – 3D Work Breakdown Structure method. (2014). Retrieved from http://breakdown233.rssing.com/chan-12384124/all_p4.html

- NORSOK standards | standard.no. (n.d.). Retrieved from https://www.standard.no/en/sectors/energi-og-klima/petroleum/norsok-standards/#.VQrkKI6UdSt

- Wibowo, G.Retrieved from http://pmworldlibrary.net/wp-content/uploads/2014/12/pmwj29-dec2014-Wibowo-WBS-Tangible-Drilling-Cost-featured-paper.pdf

- Moine, J. Y. (2013). Retrieved from http://pmworldlibrary.net/wp-content/uploads/2013/04/pmwj9-apr2013-Moine-3D-Work-Breakdown-Structure-FeaturedPaper.pdf

- Elrashid, M. (2013). MAHAKAM13: W10_Mohammed_ Our Current WBS Vs OmniClass and 3D model. Retrieved from http://aacemahakam.blogspot.com/2013/01/w10mohammed-our-current-wbs-vs.html

- Sullivan, W. G., Wicks, E. M., & Koelling, C. P. (2012). Cost-estimation techniques. In Engineering economy(15th ed., p. 101). Harlow, England: Pearson.

AWESOME, Pak Rikky!!! Really great case study and your analysis was spot on, including some really great references!!

Keep up the good work and hoping to see more blog postings like this in the coming weeks!!

I would love to see an analysis of this class schedule against the GAO’s Best Practices in Scheduling, Appendix i and Appendix III. That will not only help you achieve your objective pass one or more of the AACE exams but it will also help you analyze your own in house schedules.

BR,

Dr. PDG, Jakarta

LikeLike

Pingback: W11_OAN_WBS Selection – EMERALD AACE 2017 – WEEKLY BLOG

Pingback: W03.0_LRuiz_ PM, Procurement, Work Packages, Delivery Systems, all include in the WBS? – TEAM PHOENIX PROJECT MANAGEMENT LEARNERS GROUP

Pingback: W2.0_HN_Create 3D WBS Using NORSOK Standard Z-014 for Offshore Oil & Gas Facility Project – The Excellent AACE 2022