- Problem Definition

Our Garuda AACE 2015 Class is about to finish. This blog is to present any feedback during the class that can be useful lesson learned for the next class(es).

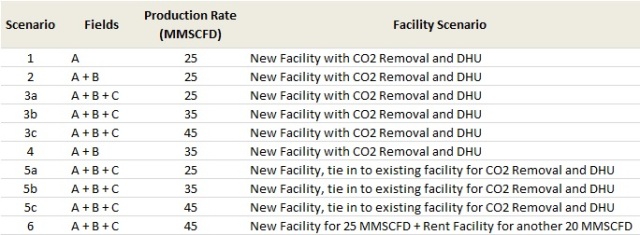

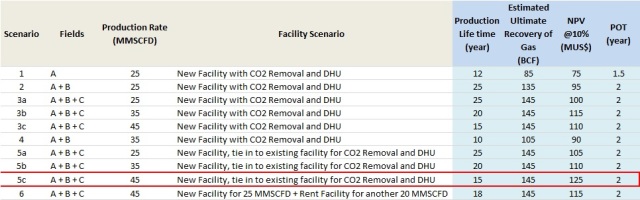

- Development of Feasible Alternatives

The main topics for this lesson learned which discussed here are :

- What would I do DIFFERENTLY if I had to take this course over again

- What tool/technique did I actually implement at work to help me generate a favorable Return on Training Investment (RoTI)

- What advice would I give to others who are going to take this course in the future

- Development of the Outcomes for Alternative

For first question “What would I do DIFFERENTLY if I had to take this course over again”, I have several ideas :

- To be able to adapt fast and make a good planning, I will read carefully lesson learned from previous classes and learned from them to make my course run easier.

- To be able to speed up on tasks given by the Client, especially blog and paper project, I will make contact directly to the outstanding performer from previous classes. Choose 2-3 good performers from them, especially who has time availability to support me as the Subject Matter Experts.

- To be able to manage the team in good form, I will remind the team how important that we choose the right person to manage the team. The person who has more time and focus to bring the team to be still on the track.

I did not do those above on my current course. For the first two items above, if I had to take this course over again, I will do them, especially to help me with paper project since I was so slow on that project , therefore I failed to finish it within the given timeframe. Start from W1, focus on this task. Try to finish it within the timeline, and do not ever slip from the schedule. Great advantage if I can pick the paper topic at the first Face to Face session so it can be discussed properly to avoid delay in writing the paper.

For second question, “What tool/technique did I actually implement at work to help me generate a favorable Return on Training Investment (RoTI)”, I have several example of tools/technique below which very useful on my daily job :

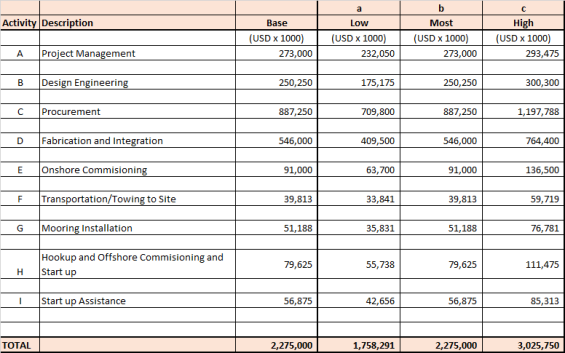

- Cost Estimate Relationship (my W2 Blog).

This was very useful when my team at work did the pre-FEED cost estimate.

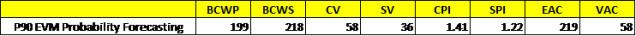

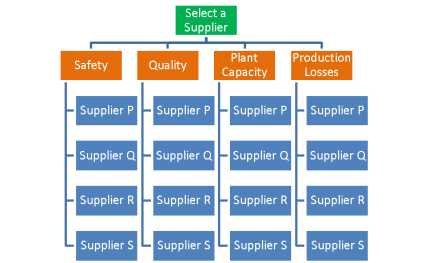

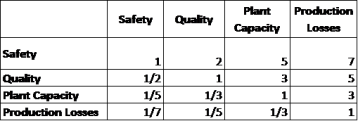

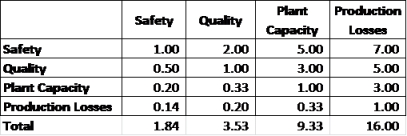

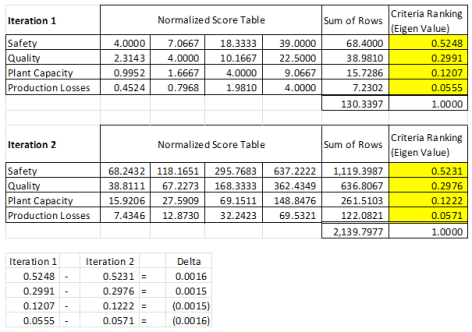

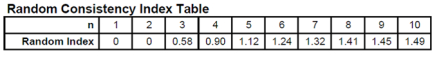

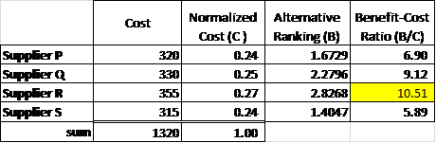

- Multi-attributes Decision Making (my W3 Blog)

This was useful when evaluated vendor quotation.

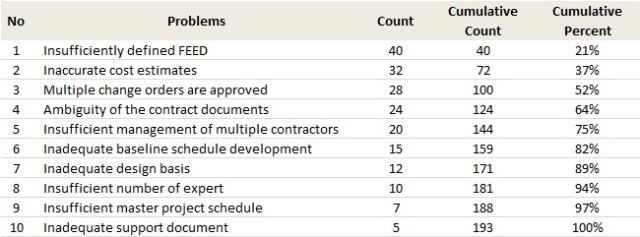

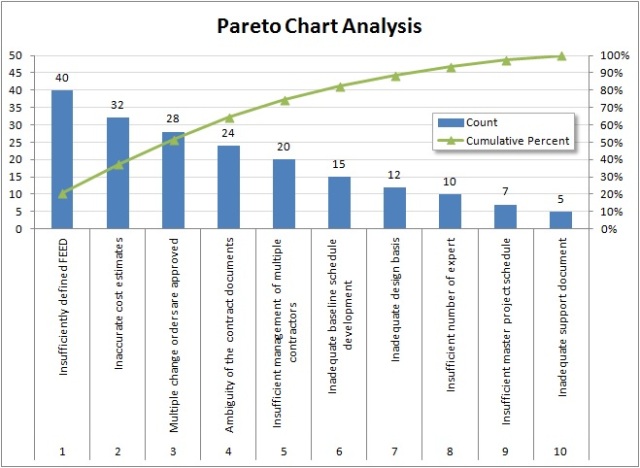

- Pareto Chart (my W4 blog)

This was useful when deal with various problem items and I need to focus on the significant problems due to the time constraint.

- WACC, Life Cycle Cost Analysis, and MARR (my W5-W7 Blog).

After learned all of them, I have confidence when I had discussion with the Economist at my work, especially WACC and MARR topics. I can contribute my idea since I had ground understanding with them, compare to the time before I took the course.

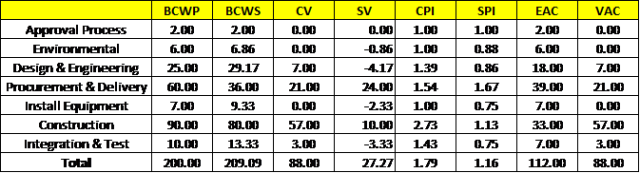

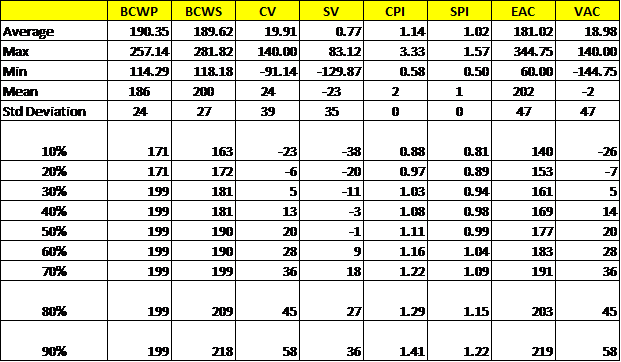

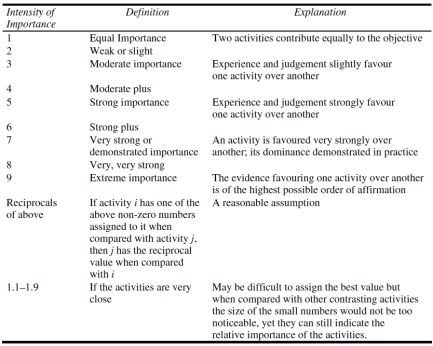

- Other such Earned Value, Force Field Analysis, Depreciation, IRR & ERR, POT, Rebaseline, etc, had provided me with a lot of techniques to complete my tasks at work

For the third question “What advice would I give to others who are going to take this course in the future”, several suggestions as per below :

- Commitment and Teamwork

Everyone should commit to every task and realize that to be able to survive we need a good teamwork. One should not be a burden to others. So plan and do this, not as an under performer.

- Plan well and use the time wisely.

We need to make a good plan of what target that we should complete each week. Be discipline and use the allocation time wisely. Once you loss the time, and out from the track (and if continuously happen), it will be very difficult to do the recovery.

- Prepare for the unexpected and take step more advance

Even if you have produced a good planning, there will be high possibility you will face the unexpected problem which will draw your time and focus out from the course, for example you get sick, your child get sick, very high load at work, etc. So it is very recommended that you take extra step in advance , or in other words make your progress advance than the plan. Create this buffer, especially in the early weeks of the course on blog and paper tasks. When the unexpected come and you do not have enough time to do the task, just release your buffer.

- Work smart, not hard.

As the mentor’s advice, “ Do not re-invented the wheel”. If you could link the topic of the blog, paper, and problem solving, and with the Client agreement, you can claim for multi progress in the same time of task. Refer to the other blog is not prohibited , however please respect the original author by put related link in the citation.

Below are the useful link for the information as mention above:

- PM World Journal : http://pmworldjournal.net/

- AACE : http://www.aacei.org/

- 2012 Class : https://aacecasablanca.wordpress.com/

- 2013 Class : https://mercureaace2013.wordpress.com/

- 2014 Class : https://kristalaace2014.wordpress.com/

- 2015 Class : https://garudaaace2015.wordpress.com/

- Citefast : http://www.citefast.com/

- Selection of the Acceptable Criteria

Any useful lesson learned above description can be utilized to get success on this course.

- Analysis and Comparison of the Alternatives

All the lesson learned above can be utilize to improve not only for this class team member but also for the next class in order to gain success to achieve the objective of the course.

- Selection of the Preferred Alternative

We can use all the lesson learned above on future classes to be well prepared prior the class start.

- Performance Monitoring and Post-Evaluation of Results

It is important to the person who take this course to be pro-active and try to implement the tools and technique in daily works for improvement so we can achieve the prime goals which are to pass one of the AACE certification at the 1st attempt and for Return on Training Investment (RoTI). Best luck with your upcoming class.

Reference:

- AACE International – Professional Resources – Recommended Practices. (2014, August 23). Retrieved from http://www.aacei.org/resources/rp/

- Project Management World Journal — A Global Resource for Continuous Learning in Program and Project Management. (2014, August 23). Retrieved from http://pmworldjournal.net/

- Darwito, R. (2015). W25_RD_Lesson Learned (Garuda AACE 2015 Class). Retrieved from https://garudaaace2015.wordpress.com/2015/08/21/w25_rd_lesson-learned-garuda-aace-2015-class/

- Citefast automatically formats citations: APA 6th edition, MLA 7th ed. and Chicago 16th ed. (2014, August 23). Retrieved from http://www.citefast.com/